All Products

-

Aluminum Swing Doors

-

Aluminum Sliding Doors

-

Aluminum Folding Doors

-

Aluminium Casement Doors

-

Aluminium Louver Doors

-

Aluminum Sun Shade Louvers

-

Aluminium Bifold Doors

-

Aluminium Pivot Doors

-

Aluminum Bathroom Doors

-

Aluminum Folding Windows

-

Aluminium Sliding Windows

-

Aluminium Tilt And Turn Windows

-

Aluminium Casement Window

-

Aluminium Swing Window

-

Aluminum Curtain Walls

-

MohammedThe best company with best aluminum Windos and Doors on the market. KLUK meet all our requirements!

MohammedThe best company with best aluminum Windos and Doors on the market. KLUK meet all our requirements! -

WilliamWith reasonable prices and high-quality products, it is difficult to find another company like KLUK.

WilliamWith reasonable prices and high-quality products, it is difficult to find another company like KLUK. -

CarlosWe purchased casement windows from KLUK for our building project, good quality and fast delivery. Highly recommended!!

CarlosWe purchased casement windows from KLUK for our building project, good quality and fast delivery. Highly recommended!!

Contact Person :

Susan Chu

Tempered Glass Aluminum Folding Windows , Horizontal Bifold Windows

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Material | Steel,Steel/Aluminum,As Per Customer's Request | Dimensions | Customer Required,Drawing,Aluminium Forging Parts,customize |

|---|---|---|---|

| Application | Machinery Parts,Industry | Process | Forging+Machining(if Need)+surface Treatment,cnc Milling,CNC Machining,die Casting Machining |

| Tolerance | +/-0.01mm,Based On The Product Structure Or Can Be Discussed,±0.20mm,Customized | Service | OEM/ODM Service,Manufacturer |

| Product Name | Machinery Parts Customized Aluminum Forging Metal Steel Forged Parts,Cold Forging Parts,Die Casting Parts,125Motorcycle Engine Casing,Factory Custom Made Cast & Forged Aluminum Die Casting Parts | Name | ISO9001 Customized 6061-T6 Aluminum Hot Forging Component,customized Precise Casting Aluminum Cold Forging Cast Iron,China Factory Custom Aluminium Forging Parts,Cold Forging Parts,forging Components |

| Size | As Customer's Request,Customer's Drawing,According To Your Drawings,Customer Size Accepted | Type | Aluminum/Zinc/Brass/Copper Die Casting,Lazer Machining,Aluminium Forging Parts |

| Quality Control | ISO9001-2008,100% Inspection Before Shipping | Item | Die Casting Aluminum Parts |

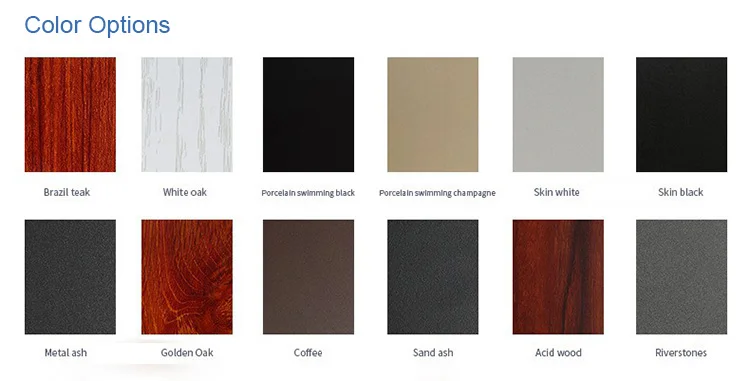

| Inspection | Mechinical Property Inspection | Color | Based On The Requirements About Surface Treatment,painting/anodizing / Polish/silk Screen/chromeplate/rubber/coating |

| Dimension | According To Product Drawing,as Per Your Samples Or Design Drawing,Customized | Serivce | ODM OEM |

| Drawing Format | .pdf / .dwg / .igs / .stp / X_t. | ||

| High Light | Tempered Glazed horizontal bifold windows,Tempered Glass Aluminum Folding Windows,Horizontal Bifold Aluminum Folding Windows |

||

Product Description

Aluminium Tempered Folding Glass Horizontal Bifold Windows

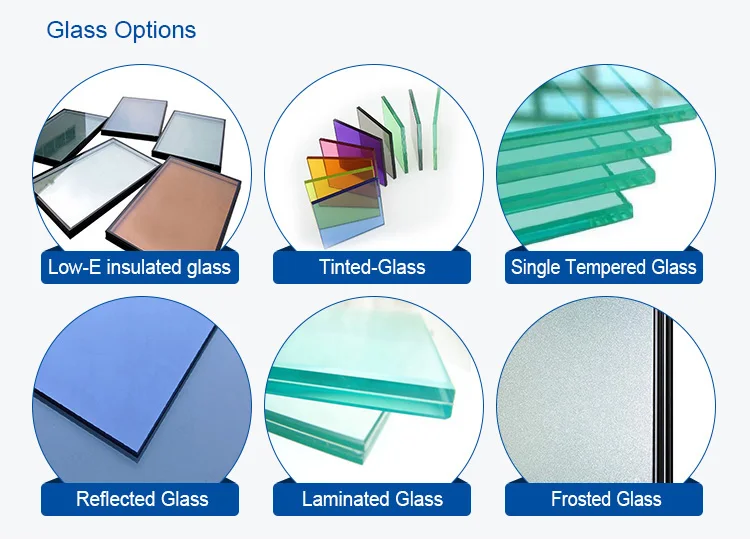

Custom Options

Product Description

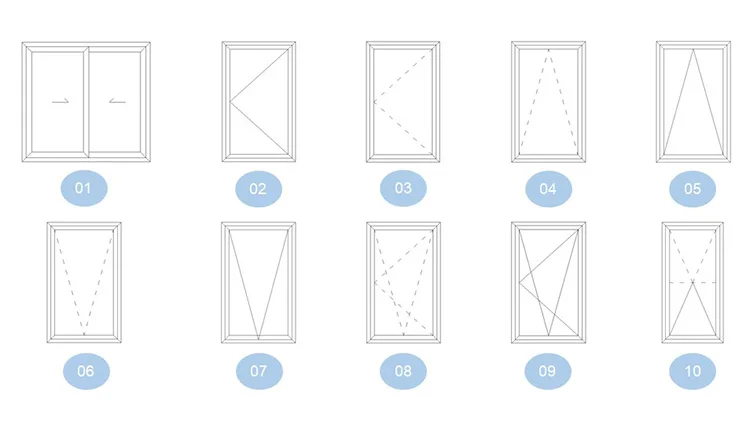

Horizontal folding window

Vertical folding window

Open Types

Clik the following pictures to view more categories

Recommended Products